Maggie nano technology (Suzhou) Co., Ltd

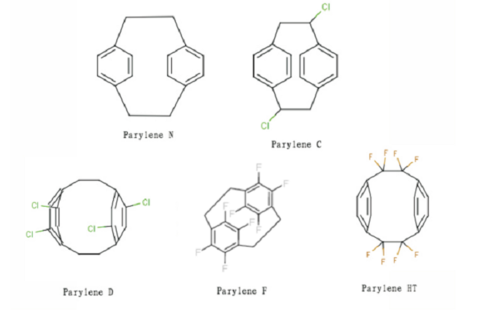

Parylene coating material N/C/D/F/HT type

The world's protective coating is a polymer of Parylene, which can be divided into N type, C type and other types according to its molecular structure.

N-type Parylene is a polymer of parxylene, bonded by poly-p-xylylene, which is linear and highly crystalline. It is highly permeable in all

types of Parylene, and can effectively form thin films on all kinds of fine seams or pinhole surfaces. It has small dielectric constant and dissipation factor, and little change with the increase of external frequency. At the same time, its very low friction coefficient makes it have excellent lubrication effect, which is mainly used in the field of silicon rubber and optics.

Type C Parylene is the aromatic group in which two hydrogen atoms are replaced by chlorine. Type C, which has a very low penetration rate of water molecules and corrosive gases, has a faster deposition rate than Type N, and a corresponding lower permeability than Type N, is the most commonly used Parylene material.

Type D Parylene, in which the four hydrogen atoms of the aromatic group are replaced by chlorine, has relative physical and electrical properties at temperature, is thermally-stable compared with types N and C, and can be deposited and polymerised very quickly, but bonding

pressures are very slow.

F-type Parylene, which replaces the H atom on dimethyl with the F atom, is a strong covalent bond, with a bond energy of up to 445kj/mol, second only to the c-h bond, so it can resist ultraviolet damage, improve its thermal stability and anti-aging properties, and has a good application prospect in aviation and semiconductor fields.

Ht-type Parylene replaces the four hydrogen atoms of the benzene ring with fluorine, and has a film with higher dielectric strength, lower

dielectric constant (i.e. better conductivity) and better thermal stability than C/N/D. The film itself is continuous, compact, no pinhole, short-term temperature resistance up to 450 degrees, long-term high temperature resistance up to 350 degrees, but also has strong uv resistance, more suitable for high frequency microwave device protection material.

Parylene coating, in addition to the above excellent protection, also has good biological compatibility, biological stability, excellent self-lubrication, coating uniformity controllability, and good physical and mechanical properties. Over the years, it has been widely used in aerospace, microelectronics, semiconductors, sensors, magnetic materials, medical equipment, cultural relic protection and other fields, and has slowly penetrated into People's Daily life.

|

|